Engineers utilise elbow fittings to redirect fluid flow within a pipeline. These components facilitate changes in the pipe’s direction. Conversely,T Pipe Fittingsserve a distinct purpose. They enable the creation of a branch line from a main pipeline. Each fitting type offers specific functionality for plumbing and piping systems.

Key Takeaways

- Elbowschange a pipe’s direction. They help pipes go around corners or obstacles.

- T Pipe Fittingscreate a new path from a main pipe. They let fluid split or join.

- Choose elbows for turns and T Pipe Fittings for branches. This depends on your project’s needs.

Understanding Elbow Pipe Fittings

What is an Elbow Fitting?

An elbow fittingserves as an essential connector. It alters the direction of pipes within a pipeline system. These components prove indispensable in various pipeline laying scenarios. This includes household water and electricity pipes, alongside industrial pipes in large factories.

Common Elbow Angles

Engineers commonly use elbows in specific angular configurations. These fittings typically come in 45-degree and 90-degree angles. These precise angles are crucial for navigating structural obstacles and space limitations within a system.

Elbow Materials and Connection Methods

Manufacturers produce elbows from various materials. Stainless steel threaded pipe fittings, for example, offer exceptional reliability and durability. Galvanised steel also provides robust options. High-pressure threaded elbows, made from stainless 316 or galvanised steel, achieve pressure ratings of 3000lbs. A 316 stainless steel female elbow typically handles 150 pounds.

Typical Elbow Applications

Elbows find extensive application across various sectors. They are indispensable in industrial processes, plumbing, and HVAC systems. These fittings prove crucial for redirecting fluid flow and navigating structural obstacles. Their use extends to chemical processing applications and outdoor irrigation systems, where resistance to corrosion is a key requirement.

Exploring T Pipe Fittings

What is a T Pipe Fitting?

A T Pipe Fitting is a plumbing component. It features a T-shaped design. This design allows a fluid stream to split into two paths or for two streams to combine into one. It creates a branch line from a main pipeline. This fitting typically has three openings. Two openings are in a straight line, and the third is at a 90-degree angle to the main line.

Types of T Pipe Fittings

Manufacturers produce various types of T Pipe Fittings. An equal tee has all three openings of the same diameter. A reducing tee features a branch opening smaller than the main line openings. This allows for a change in pipe size. Sanitary tees have a curved branch. This design promotes smooth flow and prevents clogs, especially in drainage systems.

T Pipe Fitting Materials and Connection Methods

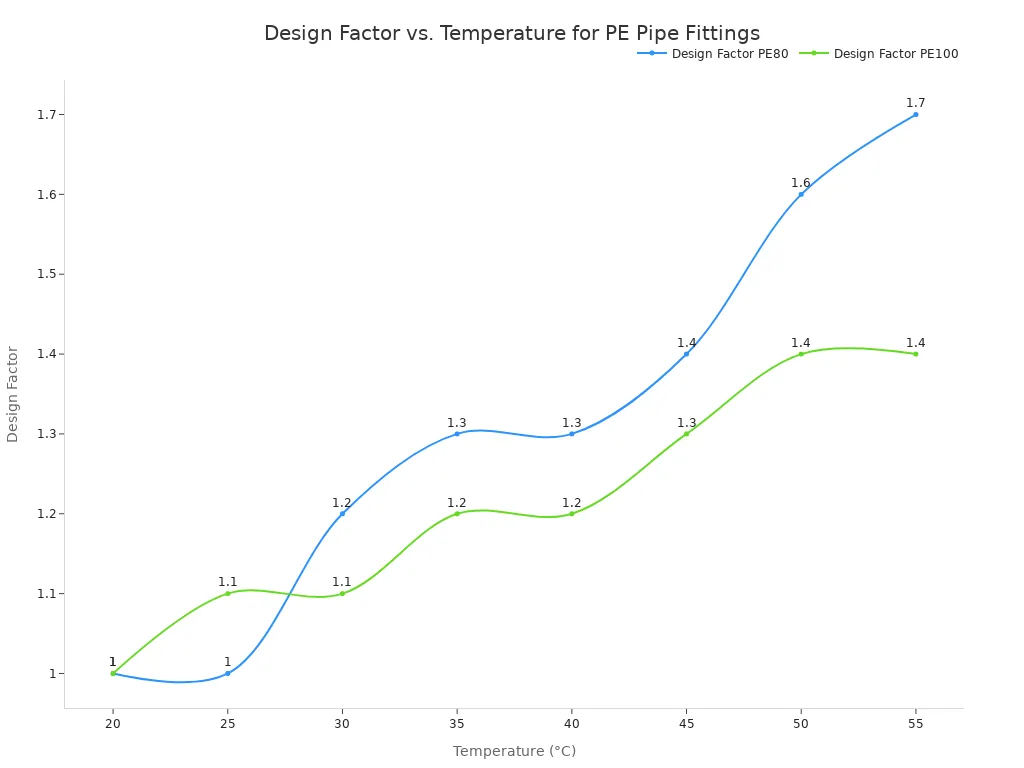

T Pipe Fittings come in many materials. These include PVC, copper, stainless steel, and various types of polyethylene (PE). Connection methods vary by material. They include threading, welding, soldering, or solvent cementing. Different materials offer specific temperature tolerances. For instance, some materials handle a wide range:

| Material Type | Minimum Operating Temperature | Maximum Operating Temperature |

|---|---|---|

| Buna N Rubber, PVC, Elastomeric (K-FLEX Pipe Fitting Insulation Tee) | -297°F | +220°F |

Polyethylene (PE) fittings also show varying temperature performance. Their design factor changes with temperature.

Typical T Pipe Fitting Applications

T Pipe Fittings are essential in many systems. They find widespread use in residential plumbing. They allow branching off a main pipe into two or more directions. They also connect multiple fixtures or appliances to a single water supply line. This includes sinks, toilets, and washing machines. In industrial settings, T Pipe Fittings divert water from a pipe. This allows a third pipe to branch off at a 90-degree angle. They are crucial for creating complex piping networks.

Key Differences Between Elbows and T Pipe Fittings

Engineers distinguish between elbows andT Pipe Fittingsbased on their fundamental roles in piping systems. Each fitting performs a unique function, influencing flow dynamics and system design.

Functionality and Flow Dynamics

Elbows primarily alter the direction of a pipeline. They maintain a single, continuous flow path. For instance, a 90-degree elbow redirects fluid flow around a corner. This action introduces some pressure drop, but the primary goal remains directional change. Conversely, T Pipe Fittings serve to create a branch line from a main pipeline. They either split a single fluid stream into two paths or combine two streams into one. This branching action inherently creates more complex flow dynamics. The fluid stream encounters a junction, leading to increased turbulence and a more significant pressure drop compared to a simple directional change.

Number of Ports

A clear distinction lies in the number of connection points, or ports, each fitting offers. Elbows typically feature two ports: one for the incoming pipe and one for the outgoing pipe. They act as a simple two-way connector for directional changes. In contrast, T Pipe Fittings possess three ports. Two ports align in a straight line, forming the main run, while the third port extends perpendicularly, creating the branch. This three-port configuration allows for the diversion or combination of fluid streams.

Impact on Flow Turbulence

Both elbows and T Pipe Fittings introduce some level of turbulence into the fluid flow. However, the degree and nature of this turbulence differ significantly. Elbows, especially those with a larger radius or a 45-degree angle, generally minimise turbulence when changing direction. A sharp 90-degree elbow creates more turbulence than a gradual bend. The fluid largely follows a curved path. T Pipe Fittings, by their very design, generate more substantial turbulence. When fluid enters the branch or splits from the main flow, it experiences abrupt changes in velocity and direction. This creates eddies and swirling patterns, leading to a greater pressure loss and increased energy consumption within the system. Engineers often consider these factors when designing efficient piping networks.

When to Choose an Elbow Fitting

Engineers select elbow fittings for specific scenarios within piping systems. Their primary function involves altering the direction of fluid flow. This makes them indispensable for various applications where a straight pipe run is not feasible or desirable.

Changing Pipe Direction

The most fundamental reason to choose anelbow fittinginvolves changing the direction of a pipeline. When a pipe needs to turn a corner, ascend, or descend, an elbow provides the necessary angular adjustment. For instance, a 90-degree elbow redirects the flow at a right angle, while a 45-degree elbow offers a more gradual turn. These fittings ensure the fluid continues its journey along a new path without interruption. They maintain the integrity of the flow, guiding it precisely where required. This directional control is crucial for routing pipes through buildings, around machinery, or along complex industrial layouts.

Navigating Obstacles

Elbows prove invaluable when a pipeline encounters physical obstacles. Buildings often present numerous structural barriers such as walls, beams, or columns. Machinery and equipment in industrial settings also demand careful pipe routing. Elbows allow installers to navigate these obstructions efficiently. They enable pipes to bypass impediments rather than requiring costly and complex structural modifications. This flexibility in routing ensures a smooth installation process and prevents potential damage to both the pipeline and surrounding structures. Engineers strategically place elbows to create a clear path for the fluid, ensuring uninterrupted operation.

Optimising Space with Elbows

Space constraints frequently dictate fitting choices in many projects. Elbows offer significant advantages for optimising available space. They allow for compact pipe layouts, which is particularly beneficial in crowded environments.

- 90° Elbows: These fittings are ideal for making sharp turns in areas with limited room. They enable pipes to hug walls or fit into tight corners, maximising the usable space.

- Short Radius (SR) Elbows: Manufacturers design these elbows specifically for space-saving. While they might introduce slightly higher flow resistance compared to long-radius elbows, their compact design makes them essential where every inch counts.

In industrial applications, elbows facilitate space-saving installations within crowded workshops. They optimise machinery performance through the precise layout of compressed air systems. Similarly, in mining operations, elbows enable the efficient routing of compressed air lines. This is crucial within confined underground spaces and around heavy equipment, ensuring the reliable operation of pneumatic controls and other vital systems. The 90-degree elbow design is particularly effective for space-saving, allowing for sharp turns in gas lines. This proves crucial in tight environments such as Caravans or RVs, where efficient routing around obstacles is necessary to conserve space.

When to Choose a T Pipe Fitting

Engineers select T Pipe Fittings for specific applications within piping systems. These components facilitate the creation of new flow paths or the integration of various system elements. Their unique design makes them indispensable for expanding or modifying existing pipelines.

Creating a Branch Line

The primary function of a T Pipe Fitting involves creating a branch line from a main pipeline. This allows fluid to divert from the primary flow path into a secondary one. For example, in a residential plumbing system, a T Pipe Fitting enables a main cold water line to supply water to both a kitchen sink and a dishwasher. In industrial settings, engineers use them to direct a portion of a process fluid to a different unit or a bypass loop. This branching capability is crucial for distributing resources or isolating sections of a system without interrupting the entire flow. The fitting ensures a secure and efficient connection for the new line.

Adding a Valve or Gauge

T Pipe Fittings offer a convenient point for installing control and monitoring devices. The third port of the fitting provides a direct access point to the pipeline. Engineers can attach a valve to this port to regulate flow, isolate a section for maintenance, or completely shut off a particular branch. Similarly, they can connect a pressure gauge or a temperature sensor to monitor system conditions. This allows operators to observe critical parameters without needing to modify the main pipeline extensively. This integration of instrumentation and control elements enhances system safety, efficiency, and operational flexibility.

Connecting Multiple Systems

T Pipe Fittings prove invaluable when connecting multiple independent systems or components. They act as a junction point, allowing different pipelines to converge or diverge. For instance, a T Pipe Fitting might connect two separate water supply lines into a single distribution pipe. Alternatively, it could split a single supply into multiple outlets, each feeding a distinct piece of equipment. This capability simplifies complex piping layouts and reduces the number of individual connections required. It streamlines the design and installation process, ensuring efficient fluid transfer between various parts of a larger network.

Installation Considerations for Both Fittings

Proper installation ensures the longevity and safety of any piping system. Engineers must consider several critical factors when fitting both elbows andT Pipe Fittings. These considerations prevent system failures and maintain operational integrity.

Material Compatibility

Selecting the correct material for fittings and pipes is paramount. Incompatible materials lead to significant issues. For example, PVC offers corrosion resistance and affordability for cold water. However, it proves unsuitable for hot water or steam applications. Copper excels in heating and potable water systems. Yet, it can corrode in specific chemical environments. Galvanised fittings degrade quickly in wet or acidic conditions. Using incompatible threads, such as British Standard Pipe with National Pipe Thread, causes cross-threading and insecure seals. This increases wear and the likelihood of leaks. High temperatures can also compromise materials. PVC softens, warps, or loses pressure tolerance above 60°C, leading to structural failure.

Pressure and Temperature Ratings

Fittings must withstand the operational pressures and temperatures of the system. Exceeding these ratings causes material degradation and potential failure. Industry standards dictate rigorous testing. For pressure mains, engineers conduct hydrostatic tests after trench filling. These tests involve minimum pressures of 1050 kPa for mains up to DN300. They maintain the specified pressure for four hours after a 12-hour stabilisation period. A pressure loss greater than 50 kPa indicates failure. Sewer gravity mains undergo air or hydrostatic tests. Low-pressure air tests involve an initial pressure of approximately 27 kPa. The system must maintain this pressure with a loss of less than 7 kPa over a specified time.

Ensuring Proper Sealing

A leak-free seal is crucial for system performance. For threaded fittings, a suitable thread sealant is essential. When working with gas lines, use a high-quality sealant specifically designed for gas applications. PTFE tape, also known as Teflon tape, can be used. Ensure it is rated for gas and apply it evenly without excessive wrapping. This prevents blockages or leaks. Welded fittings create extremely strong connections. They suit high-pressure environments. Flared fittings use a 37° flare for a tight, metal-to-metal seal. Compression fittings rely on a ferrule that compresses around the pipe. This provides a simple, reliable, and leak-proof seal. Crimp fittings are compact and durable. They are crimped onto the hose end using a hydraulic tool. Improper installation, such as incorrect crimping or poor assembly, often leads to fitting failure.

Engineers select elbows to alter pipeline direction effectively. They utilise T Pipe Fittings for creating branch lines within a system. Optimal fitting choice always depends on specific project requirements. Consider factors such as flow dynamics, available space, and overall system complexity carefully to ensure efficient and reliable operation.

FAQ

What is the main difference between an elbow and a T Pipe Fitting?

An elbow changes the pipeline’s direction. AT Pipe Fittingcreates a branch line, allowing fluid diversion or connection of multiple systems.

Do these fittings affect fluid flow?

Yes, both fittings introduce turbulence and pressure drop. T Pipe Fittings generally cause more turbulence due to the branching action compared to elbows.

When should I choose an elbow over a T Pipe Fitting?

Choose an elbow when you need to change the pipeline’s direction or navigate obstacles. It maintains a single, continuous flow path.

Post time: Oct-29-2025